How Dispensing Tools Work

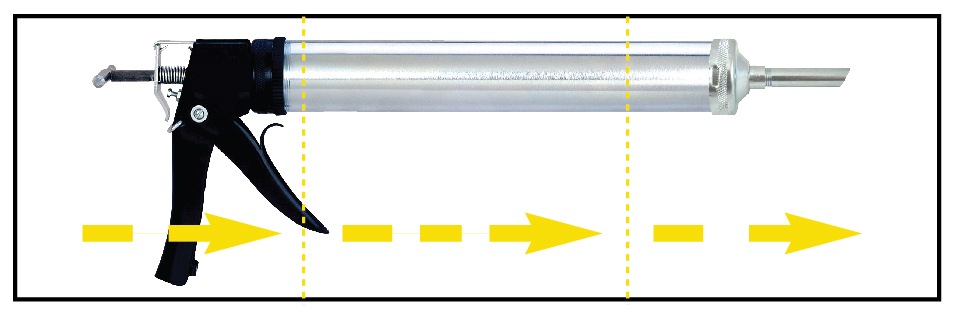

There are 3 core components in a dispensing tool: The Drive, the Material Containment Unit (MCU), and Nozzle. By customizing these components to meet your specific application needs, you can create the optimal dispensing tool.

Drive: Creates initial force or thrust

Material Containment Unit (MCU): Holds the bulk, sausage, or cartridge material

Nozzle: Distributes material in desired size and shape

Drive

Mechanism that creates force lbf or thrust. Three types available:

- Manual: hand operated, portable, and efficient. Drive ratios (Mechanical Advantage) from 5:1 to 26:1 are available to match the viscosity or nozzle back pressure.

- Air-Powered: requires an air compressor, regulator, and hose. Portable tanks work also. This set-up is best for industrial applications.

- Cordless: portable, powerful, fast and effortless.

Material Containment Unit (MCU)

Contains the material to be dispensed. Manages the pressure created by the drive.

- Bulk Material: Sealants and adhesive supplied in pails

- Sausage Packs: Packaged in a Mylar bag which fits a sausage specific tool

- Cartridges: Portable and convenient. Single and 2K two-component

Nozzle

Determines size and shape of the dispensed material

- Lengths from 3″ to 24″+

- Widths from 3/64th” to 4″

- Shape: round, triangular, slot, oval, ribbon, multi-bead

- Material: Steel, aluminum, plastic

- Standard and static (motionless) mixing nozzles

- Straight, bent, and bendable