Smooth Rod Caulk Gun & “Dripless” … What Happens

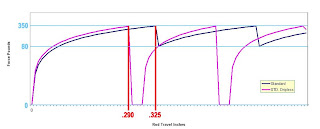

This graph is interesting to talk about. It illustrates the measured results of a standard smooth-rod drive tool versus a similar dripless style tool. The blue line shows the force generated by the standard drive system. Note the small drop in force between each pump. It also shows the displacement (amount of material dispensed) of the drive system with each pump.

The purple line shows the exact same action using an equivalent drive system with a dripless feature. Note that the force drops to zero at the finish of every stroke and the displacement is about 20% less per pump.

What happens? The smooth rod drive tool allows the operator to pump efficient, smooth, long beads of sealant. Conversely, with the dripless drive, at the conclusion of each pump there will be a dramatic bump or lump in the bead.

Conclusion: Choose the right tool for the job! Smooth rod tools are excellent for applications where the bead requires more then one stroke. Dripless is better for small beads or multiple, repetitive dabs such as interior paint prep where you are filling short cracks, nail heads or depressions intermittently.

There is a reason and an application for both types of drive systems.